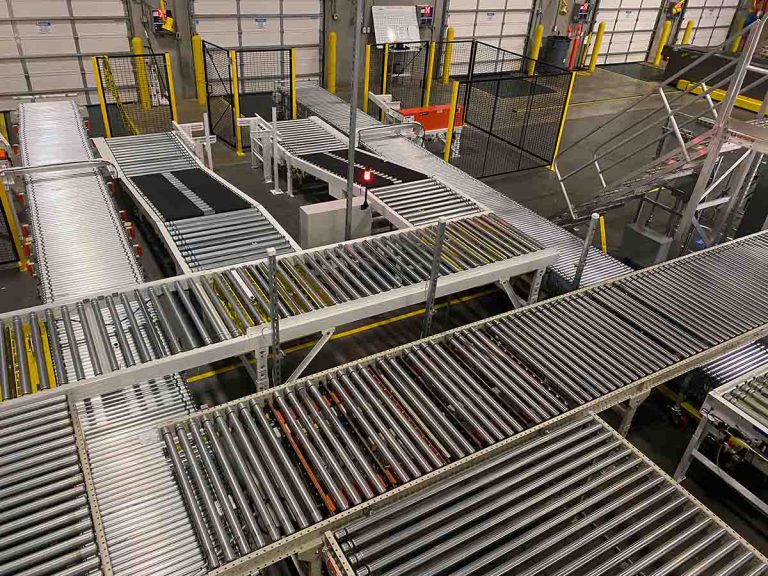

24 Volt DC MDR Conveyors: What They Are and Where To Use Them

24 Volt DC Motor Driven Roller (MDR) conveyors have transformed how materials move in warehouses, distribution centers and manufacturing facilities. With built-in motors, modular designs and zero-pressure accumulation (ZPA) capabilities, these conveyors offer unparalleled energy efficiency, easy maintenance and smooth product handling.

At Material Handling Technologies (MHT), we provide innovative 24V MDR conveyor solutions that improve productivity and reduce operating costs. Explore how MDR conveyors work, their advantages and the applications where they work best.

Find Your SolutionThe Basics of 24 Volt DC and MDR Technology

Unlike traditional conveyor systems with external motors and complex power transmission components, MDR conveyors (the first two listed) are self-contained and modular.

Key Overall Features:

- Motors: A roller per section has its own motor for precise control.

- ZPA Functionality: Ensures products accumulate without touching, reducing the risk of damage.

- Plug-and-Play Design: Simplifies installation and minimizes setup time.

Let’s cover their features even further.

Drive Rollers

MDR conveyors have at least one “drive roller” per conveyor section that is supported by an integrated 24V DC motor. This roller also has a power cable coming out of one end that you plug into the “drive card” or “control card.”

Control Card

The logic needed to program the control card is often pre-packaged in the card itself when it arrives from the manufacturer. Typically, a generic 6-pin communication cable (similar to a phone cable) is used to connect it, with the same cable plugging into the downstream zone and another cable linking to the upstream zone.

At MHT, we add a photo-eye or sensor that is also plugged into this control card. We also use bands or O-rings to connect this drive roller to carrier rollers that are ahead (downstream) and behind (upstream) of the drive roller. By doing this, the cables act as the link to send messages between the cards after receiving feedback from the photo-eyes that report back to the card whether they are blocked (i.e., the product is in the path of the sensor) or clear (i.e., the product is NOT in the path of the sensor).

What Are the Advantages of MDR Conveyors?

There is a time and a place for the other styles of conveyors. However, when you have a zero-pressure accumulation application, need an accumulation buffer or want to install a shorter run, a 24 Volt DC MDR conveyor is the best choice.

Zero Pressure Accumulation

Also known as ZPA for short, this is the most common reason to use a 24V DC conveyor. This technology ensures that boxes or products accumulate but do not touch, without any programming needs.

For instance, you may have a pick-and-pack operation or an order fulfillment system where you want some buffer factor in the unloading process to minimize the backup of your transportation conveyor. Or, maybe you want an accumulation buffer when receiving boxes off your brand-new high-speed sorter.

While other types of conveyors can offer ZPA, our 24-volt DC MDR conveyors are truly the premium option.

Easy Maintenance

Say goodbye to complicated pneumatics and airbags. The modular nature of MDR conveyors makes maintenance much simpler, reducing downtime when you do need to replace a component.

Reduces Energy Consumption

Compared to more traditional 460v/3ph motor conveyors, each zone is only on when the product is either present in a zone or if the upstream photo-eye is blocked. A zone will also only stay on briefly after a product is downstream of that zone, resulting in massive energy savings.

Easy Installation

Aside from all of the aforementioned components, you only need a 24VDC power source. There are no belts to track, motors to wire, VFDs to program or other tedious tasks, making it truly “plug and play.”

Best Applications For 24 Volt DC MDR Conveyors

MDR conveyors are ideal to use in:

- Order Fulfillment Centers: ZPA technology ensures smooth handling of packaged goods.

- E-Commerce Warehouses: Energy-efficient operation and modular designs accommodate fluctuating demands.

- Manufacturing Lines: Handle delicate or heavy components with precision.

- Cross-Docking Operations: Streamline product flow while reducing labor-intensive handling.

Need a 24 Volt DC MDR Conveyor? Choose MHT

At MHT, we combine decades of experience with cutting-edge technology to deliver MDR conveyor systems tailored to your needs. Our in-house engineering and fabrication teams ensure: