The Different Types of Cranes and Their Purposes

In New York, where efficiency and space are at a premium, material handling cranes play a vital role in keeping operations running smoothly, safely and with minimal downtime across industries. Whether you’re managing a shipping facility in Buffalo or overseeing manufacturing in Albany, understanding the different types of cranes and their specific purposes can help your business thrive.

Types of Material Handling Cranes and Their Uses

Cranes are used to transport loads that would be otherwise impossible or too time-consuming to move manually. They improve efficiency, reduce labor costs and ensure safety in handling large or awkwardly shaped materials. Each type of crane has a specific purpose and limits, which we outline below:

Bridge Cranes

Bridge cranes, also known as overhead cranes, are essential for New York’s high-density environments, where maximizing vertical space is crucial.

They are highly versatile and efficient for moving heavy loads.

They reduce physical labor on workers and can minimize the risk of accidents by providing controlled lifting and transportation of heavy items.

Plus, they effectively free up your floor space for other operations.

With Material Handling Technologies’ expertise, we can customize bridge cranes to fit the unique structural requirements of your New York facility, ensuring seamless integration with your existing systems.

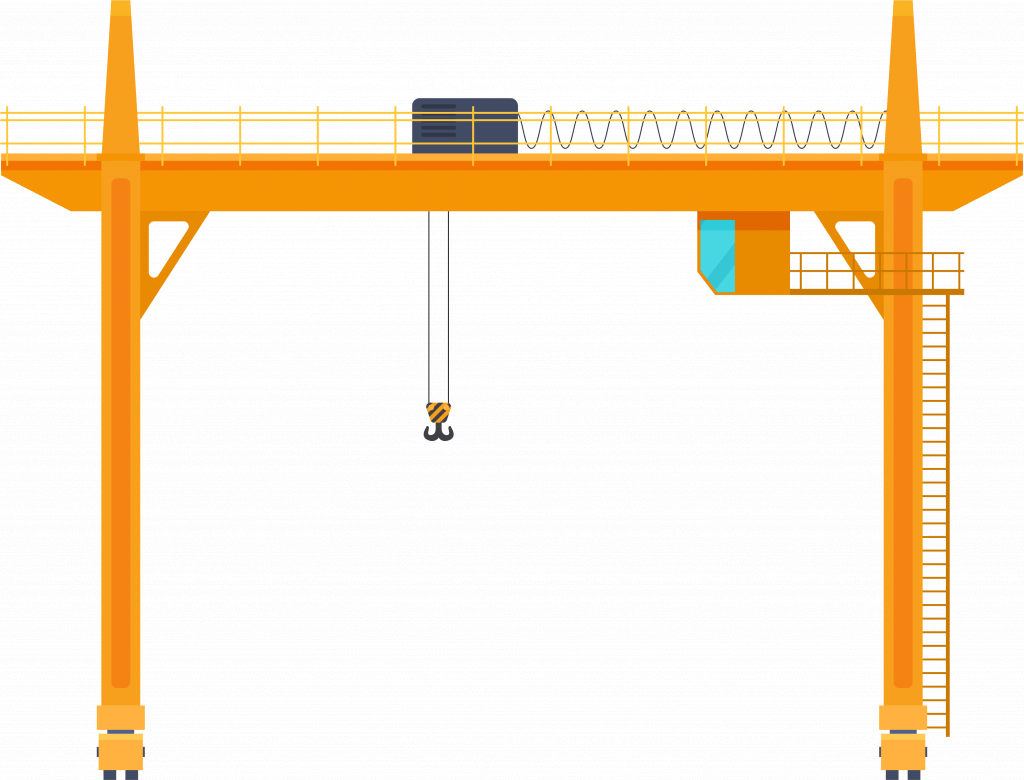

Gantry Cranes

Gantry cranes are a large type of overhead crane with a single or double girder configuration supported by freestanding legs that move on wheels or along a track or rail system.

The structure of a gantry crane allows them to straddle an object or workspace, making them ideal for lifting heavy loads in open environments.

Unlike bridge cranes, which are typically mounted on the ceiling of a facility, they are mobile and can be used both indoors and outdoors.

They also can operate in areas where traditional overhead cranes cannot, such as areas with limited overhead clearance.

Available in various sizes and configurations, gantry cranes are often less expensive to install and maintain compared to bridge cranes, especially in facilities without existing support structures. And, because they are adjustable and portable, they can adapt to different working environments, making them ideal for New York facilities with varying needs.

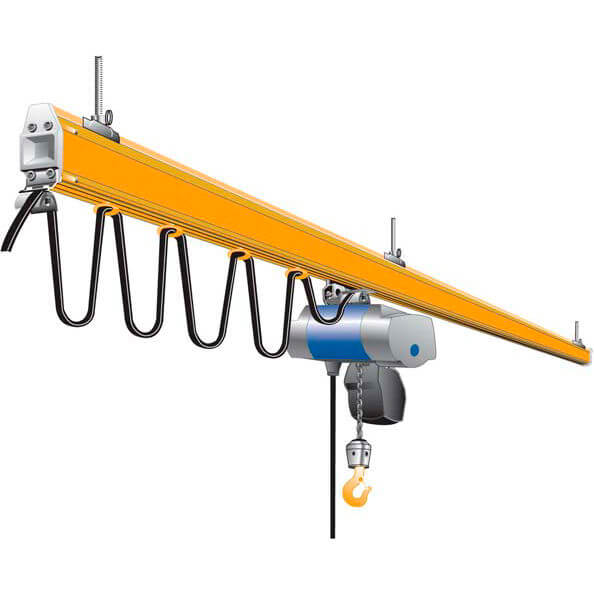

Jib Cranes

For New York businesses that demand precise material handling in confined spaces, jib cranes offer the perfect solution.

Jib cranes are known for their flexibility and efficiency in lifting and moving heavy materials within a specific area.

They are often used for repetitive lifting tasks, such as moving parts between workstations or loading machines.

The hoist and trolley system of a jib crane allows for precise positioning of loads, making them ideal for tasks that require accuracy.

Wall-mounted and wall-traveling jib cranes maximize floor space, while free-standing cranes provide extensive coverage without requiring a large footprint. Compared to larger cranes like bridge or gantry cranes, jib cranes are often more affordable and easier to install, especially in smaller facilities.

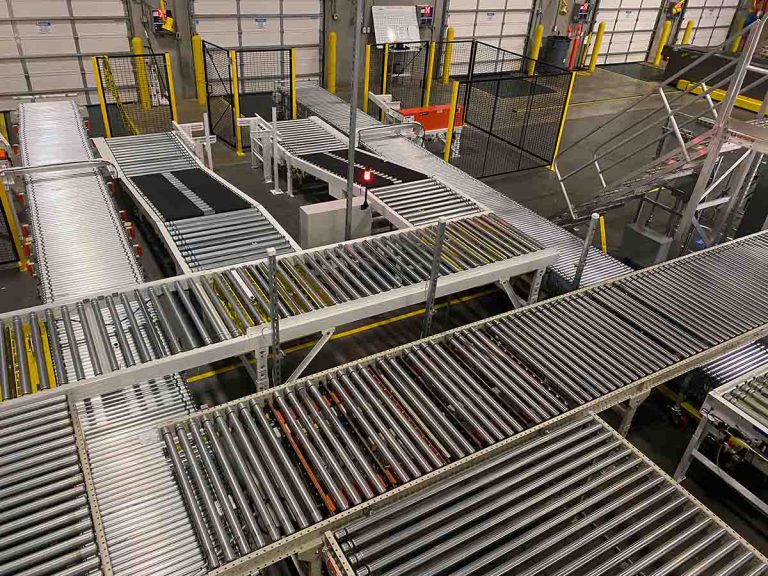

Monorail Cranes

Monorail cranes are a specialized type of overhead crane that operate on a single rail, typically mounted on the ceiling or a support structure.

These cranes are designed for straightforward and linear lifting and moving tasks from point A to point B.

As such, monorail cranes are typically used for assembly line operations where components need to be moved between workstations or along a production line.

Monorail cranes are highly efficient for moving loads along a fixed path.

By mounting the rail overhead, they can free up valuable floor space, making them ideal for facilities with limited room. Plus, the monorail track can be designed to follow the exact layout of the facility, including curves and slopes to meet all your specific operational needs. With fewer moving parts than other types of cranes, monorail systems are generally easier to maintain, resulting in less downtime.

Choosing the Right Crane with Material Handling Technologies

For businesses looking to optimize their material handling processes, our custom crane solutions are designed to meet the demands of the fast-paced, space-constrained environments. Selecting the right crane for your operational goals requires not only considering load capacity and reach but also understanding the unique challenges of making facility operations more efficient.

Whether it’s navigating city regulations, adapting to limited space or ensuring your crane is equipped to handle all your business’s demands, our team at Material Handling Technologies has the local expertise to guide you. While we serve businesses across industries all over North America, we have a regional office in Syracuse so you can find us in your area! Call us at 1-800-779-2476 or contact us today.