Why Powder Coating is the Best Choice for Your Material Handling Needs

Material handling equipment needs durable finishes, and powder coating provides exactly that. Known for its long-lasting efficiency and sleek finish, it’s an increasingly popular solution for demanding scenarios. Let’s dive into what makes it so effective, the benefits it offers and how in-house applications can take it even further.

What is Powder Coating?

Powder coating is a dry finishing process where a fine powder—typically made of polymer resin, pigments and other additives—is electrostatically applied to a metal surface (no solvents needed). It’s available in two primary types: thermosetting and thermoplastic.

- Thermosetting powders cure under heat to form a strong, irreversible chemical bond, making them ideal for permanent applications.

- Thermoplastic powders melt and flow into a protective layer without chemically cross-linking, allowing them to be reheated and reshaped as needed.

Once the powder type is selected, the process begins with surface preparation—typically cleaning and possibly abrasive blasting—to ensure proper adhesion. The powder is then applied using an electrostatic spray gun that charges the particles, helping them stick evenly to the surface. Finally, the coated equipment is heated in an oven, where the powder forms a protective finish.

CONTACT US WITH POWDER COATING QUESTIONS

The Key Benefits of Powder Coating for Material Handling Equipment

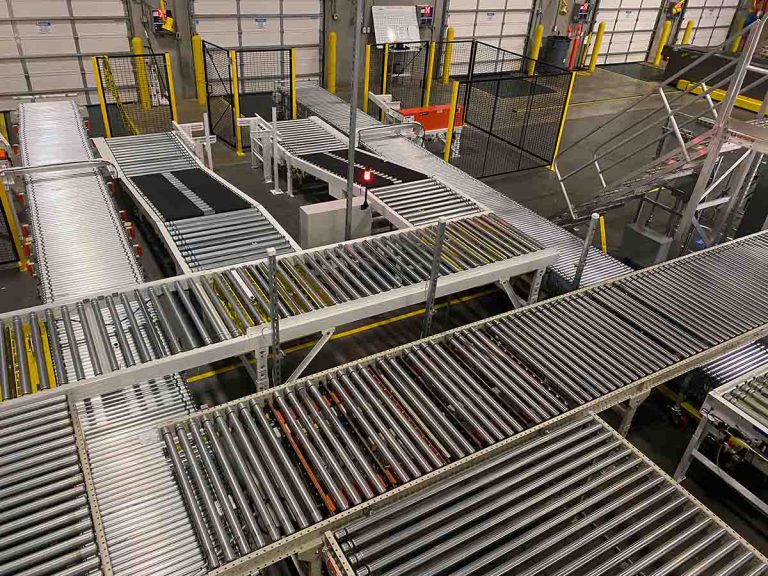

Essential equipment types, such as vertical lifts and conveyors, are subjected to constant use, heavy loads and frequent movement. When compared to traditional paint finishes, powder coating has clear advantages for equipment to operate longer, stay cleaner and have a more professional appearance:

1. Durability and Longevity

Powder coating outlasts other finishes, helping your equipment stay in service longer by:

- Offering built-in protection against chemicals, moisture, UV rays and resistance to chipping, scratching, fading and wear.

- Holding up in harsh environments, outdoor conditions and heavy-duty use.

2. Environmental Benefits

Powder coating supports sustainable operations by:

- Containing no solvents or VOCs, reducing harmful emissions.

- Minimizing waste and overspray when efficiently applied.

3. Aesthetics and Variety of Finishes

Powder coating enhances equipment appearances by:

- Being available in a wide range of colors, finishes and textures.

- Delivering a clean, uniform appearance.

- Enabling full customization to match your brand or project needs.

4. Cost-Effectiveness Over Time

Powder coating offers more value for your equipment investment by:

- Reducing maintenance costs, repair needs and downtime.

- Extending equipment lifespan, delaying replacements.

Ready to get more from your finish? Discuss your needs with our in-house powder coating experts today.

Why Choose a Company That Offers In-House Powder Coating Services?

Choosing a company with in-house powder coating services enhances the above benefits even further—ensuring quality control, customization, faster turnaround times and long-term savings.

1. Quality Control and Inventory Management

You maintain full control at every stage, ensuring smarter operations and more consistent results through:

- Direct control over surface preparation, application and curing.

- Faster adjustments to troubleshoot issues and ensure batch consistency.

- Streamlined inventory management for tracking materials, finishes and coated products.

- Less waste and tighter stock control through end-to-end process visibility.

2. Flexibility and Customization

You have the freedom to meet unique color, finish and texture requirements in a way that external providers often can’t:

- Faster turnaround for customized material handling equipment.

- Quick adjustments to project changes or specific requests.

- Cost-effective small-batch production for custom or limited-edition products.

3. Efficiency and Faster Turnaround with Improved Communication

You can streamline and tailor your production schedule to meet specific needs, meaning:

- Reduced lead times thanks to a fully integrated process.

- No reliance on third-party providers, which can slow project timelines.

- Improved coordination between powder coating and other departments—such as design or assembly—reducing errors and enhancing workflows.

4. Cost Efficiency

You can eliminate expensive third-party costs and gain better control over pricing, particularly for high-volume production. This allows you to pass on even more savings to your customers.

Partner With Material Handling Technologies for Powder Coating Finishing Solutions

Ready for finishes that stand the test of time, from a business with over thirty years of proven results? At MHT, we understand the unique demands of material handling and offer top-quality solutions custom to your needs. Contact us today to discuss reliable powder coating paired with the high-quality material handling equipment you deserve.