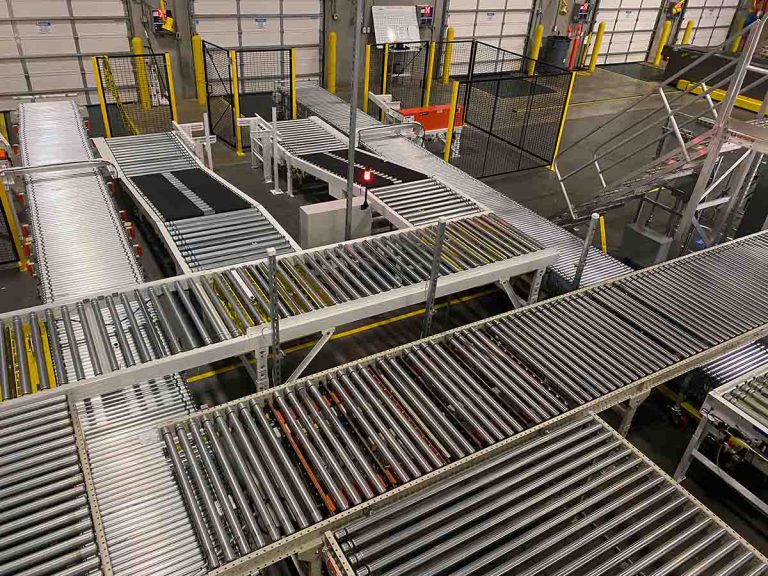

Our Conveyors

Whether you are looking for a turn-key conveyor system, a piece of gravity conveyor, or something in between, we offer innovative solutions every step of the way.

AC Powered Case Conveyor

AC Powered Pallet Conveyor

Sortation Conveyor

Extendables & Flexible Conveyors

Spirals

Gravity Conveyor Tile