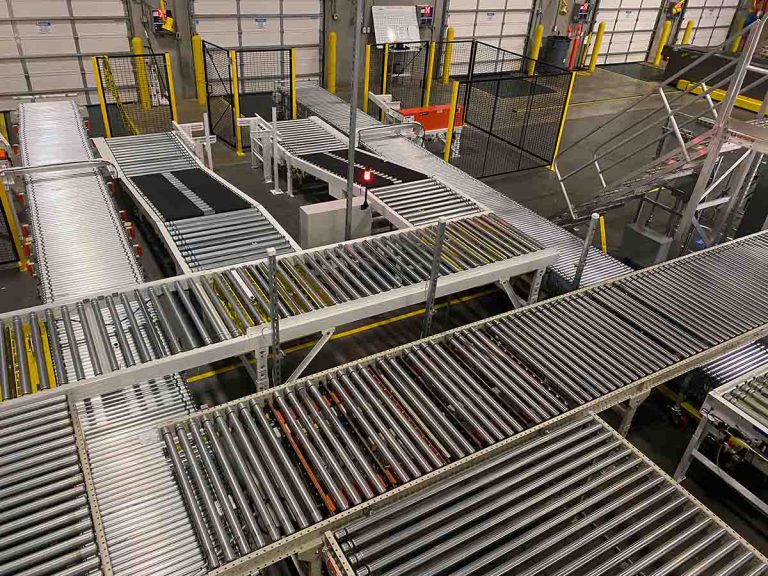

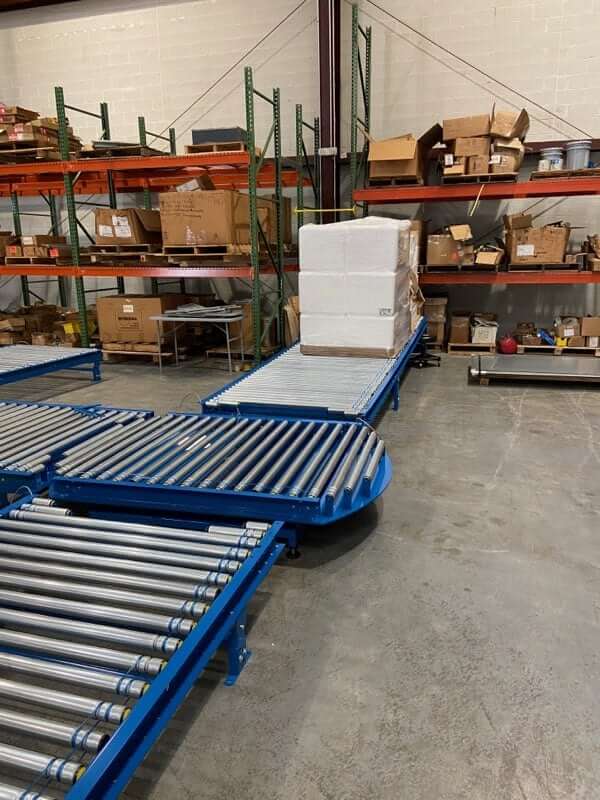

Conveyors & Sortation Systems

Material Handling Technologies (MHT) is a systems integrator with a specialized emphasis on conveyor and sortation systems. We have a full range of capabilities whether you are in need of conveyor solution or a fully integrated sortation conveyor system.

With in-house groups specializing in systems engineering, controls engineering, fabrication, and installation, we have the resources to bring your vision to life. Let us know how we can help design and integrate your next turn-key conveyor and/or or sortation system solution.

Contact Us Explore Conveyors