How To Inspect Belt Conveyor Systems: A Complete Checklist

When was the last time you thoroughly checked your conveyor belt system? Regularly “walking the belt” as it’s known is essential for identifying potential issues and ensuring its performance. To help keep your operations running smoothly, here’s a belt conveyor inspection checklist that covers what you need to know and do.

Why Regular Belt Conveyor Inspections Are Important

Routine inspections not only minimize downtime but also offer these critical benefits:

More Reliable Production Processes

Early detection of problems helps prevent bottlenecks and ensure profitability.

Maximized Equipment Lifespan, Minimized Costs

Addressing issues early helps you avoid expensive breakdowns and lower long-term spending.

Enhanced Worker Safety

Resolving hazards helps ensure compliance with OSHA regulations and reduces the risks of workplace accidents.

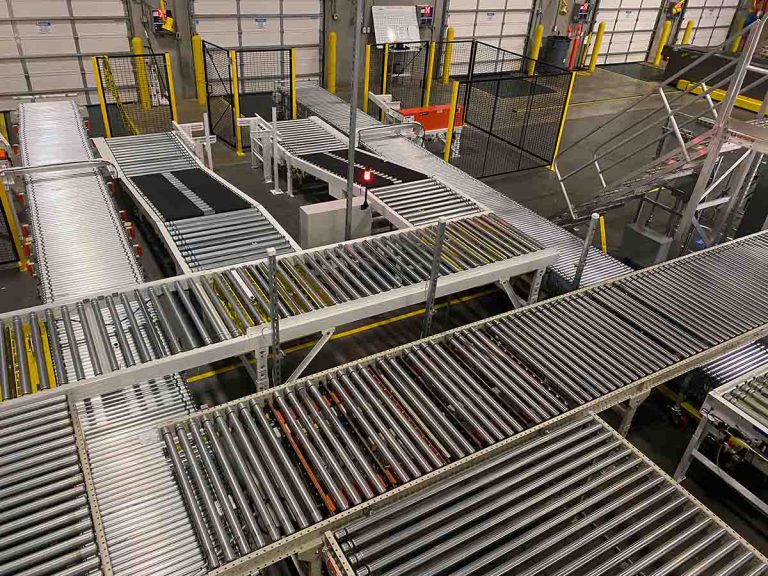

Key Areas to Inspect in Belt Conveyor Systems

Effective inspections require thorough documentation and careful observation. On a daily, weekly and monthly basis, it’s best to capture your findings as part of a detailed log that includes:

- Photos of critical components.

- Detailed inspection notes.

- Complete belt revolution observations.

Daily Belt Conveyor Inspection Checklist

Monitor for general issues like damage, dirt buildup, delamination and misalignment. Additionally:

- Listen for unusual noises (e.g., grinding or squeaking).

- Check for non-moving or worn-out rollers.

- Test safety mechanisms—including emergency stops, alarms and sensors.

Weekly Belt Conveyor Inspection Checklist

Motors and Drives

- Use a tension gauge to check and adjust drive belt tension as needed.

- Look for signs of overheating, such as discoloration or unusual smells.

Bearings and Pulleys

- Confirm smooth movement and proper lubrication of all bearings.

- Inspect pulleys for wear, cracks or other damage.

Monthly Belt Conveyor Inspection Checklist

Conveyor Structure and Frame

- Check for rust, cracks or misalignment that could compromise structural integrity.

- Check for loose hardware and tighten as necessary.

Electrical Components

- Inspect wiring for damage, corrosion or loose connections.

- Test electrical systems to prevent short circuits and ensure functionality.

What To Do After Finishing The Checklist

Once you have a holistic view of your conveyor belt system issues, it’s best to differentiate which ones require immediate attention and which need preventive maintenance. For persistent or complex problems, a new custom conveyor solution could be more cost-effective and efficient than retrofitting your conveyor equipment. Our experts are available to help you explore the most effective solutions for your belt conveyor system needs.

Contact Us for Expert Conveyor Belt System Support

With Material Handling Technologies, you have direct access to expert conveyor belt services that help maximize the results of your inspections.

Request your consultation today by completing our form or calling:

Southeast US: 1-800-779-2475

Northeast US: 1-800-779-2476